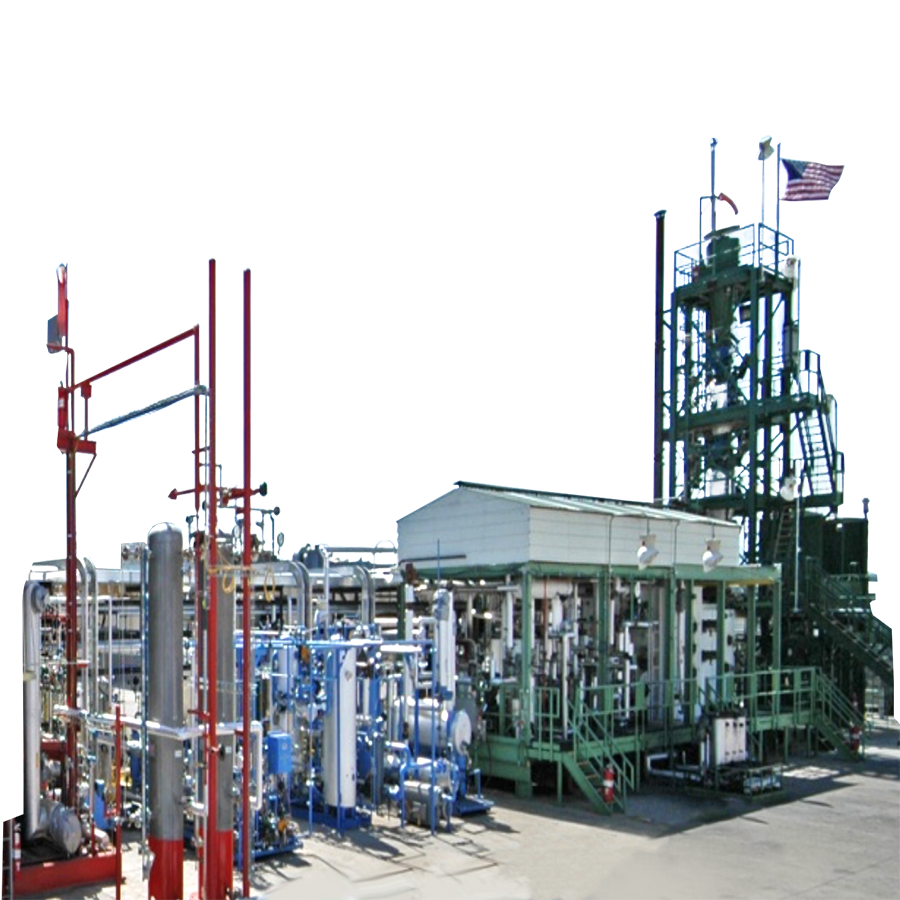

A proprietary process to turn waste into energy

Our Patented Process...

We convert organic carbonaceous feedstocks such as biomass, wood chips, tires, medical waste, municipal solid waste, coal and petroleum coke.

Converts Feedstocks...

Devolatilization is a continuous feed, closed loop process utilizing heat in the absence of oxygen to produce high value energy products.

To ultra-clean fuels

Utilizing Fischer Tropsch, catalytic or other (direct and indirect) liquefaction processes to produce quality synthetic solvents, transportation and commercial fuels.

Environmentally friendly waste-to-fuel conversion

Conventional gasification plants produce a constituency of pollutants. Our patented process discourages oxygen in the reaction, eliminating internal feedstock combustion. Slag, “Flash Pyrolysis” and “Run Away” are eliminated. Excess heat, CO2 and other harmful combustion products are avoided.

Reducing the volume of landfill waste by 90%

There is currently an abundance of potential sources of energy in waste coal deposits, municipal and commercial waste, scrap tires, medical waste and plastics.

Carbon2Fuels produces valuable energy and fuel products in an environmentally friendly manner, reducing the flow of waste to landfills and other waste impoundments.

What is Carbon Transition?

Our process ‘transitions’ carbon molecules without oxygen, liberating and reforming the feed. This is a continuous process, producing a flow into high quality syngas, which can be formulated to meet specific goals. This continuous feed process operates in a closed loop environment, maintaining control of the overall transitioning process.

Become a Partner or Investor Today

Contact us by email or send us a message